Gas valve interlock controls

A range of gas valve interlock controls for kitchen extract systems where airflow is required prior to the electrical supply to the gas valve solenoid being enabled.

Why is it needed?

All kitchens are required to have a good ventilation system that provides ample airflow in and out to avoid the accumulation of dangerous gases such as carbon monoxide. An interlock is used to monitor airflow to help maintain kitchen safety.

How does it work?

There are 2 ways that the gas valve interlock can check whether the ventilation is present. Firstly air pressure differential switches can be fitted to the ductwork or secondly current sensors can be fitted to monitor the fans. In either case if the method used detects a loss of airflow then the gas valve will close.

The GVI-001 and GVI-002 require the addition of either pressure switch(es) or current switch(es). If both the supply fan and extract fan are being monitored you will need 2 pressure switches or 2 current switches.

When used with pressure switch(es) the electrical supply to the gas valve solenoid will be enabled when airflow is proved. When used with current switches(es) the electrical supply to the gas valve solenoid will be enabled when current flow is proved.

Both the GVI-001 and GVI-002 have the facility to connect an emergency stop button.

Please note that both the GVI-001 and GVI-002 only monitor the fan airflow/current and do not start/stop the fan. For fan starters/controllers please refer to catalogue

Pressure switch

Current sensor

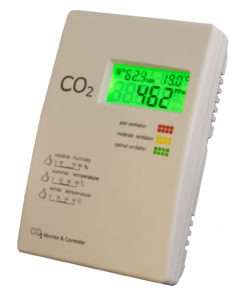

CO2 sensor

Emergency stop button

We offer a range of ancillaries to be used in conjunction with our gas valve interlock controls.

See Page 16 of catalogue for further details.